STATE-OF-THE-ART TECHNOLOGY

Machine learning algorithms. Self-learned classification

INCREASE PRODUCTIVITY

High throughput & automated processing. Instant data recording.

SEAMLESS INTEGRATION

IR 4.0 Ready. Customizable to existing workflow.

CONSISTENT RESULTS

100% QC check eliminate human errors.

Key Features

Object Counting |

|

|

|

Count samples fast, works with all major cameras, is customizable, and easily integrates into any process or machine. |

|---|---|

Offset Measurement |

|

|

|

User configurable tolerance for the inspected parts. Overall results are available in a glance. |

|---|---|

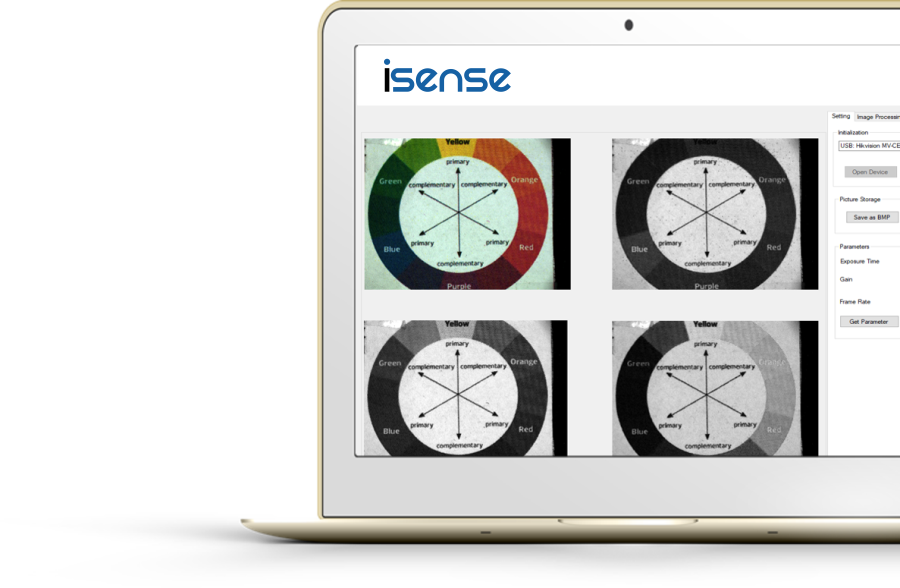

Template Matching |

|

|

|

Efficient QC, solution with instant golden sample setup for similarity comparison. Clear ‘PASS’ & ‘FAIL’ indicators enable quick judgement by process owners. |

|---|---|

Smart Defect Detection |

|

|

|

Simple setup with user-configurable part tolerance. Quickly detects complex defects, with overall results easily viewable at a glance. |

|---|---|

Smart AI Vision

Product Information

Model |

AIV Object Counting |

AIV Offset Measurement |

AIV Template Matching |

AIV Advanced Defect Detection |

|---|---|---|---|---|

| Key Features | An efficient solution for QC test with the capability of setting golden sample for similarity comparison within seconds | Simple and ease setup with user configurable tolerance for the inspected parts. Offset measurement up to 0.01mm within seconds and the overall results are available in a glance. | Simple and ease setup with user configurable tolerance for the inspected parts. Automatically count objects within seconds and the overall results are available in a glance | Simple and ease setup with user configurable tolerance for the inspected parts. Capable of detecting defects that are complex in nature. within seconds and the overall results are available in a glance. |

| Hardware Configuration | 1.3 MP Mono Color Camera | 1.3 MP Mono Color Camera | 1.3 MP Mono Color Camera | Dell AI Workstation (i3) |

| 6mm Lens | 16mm Lens | 16mm Lens | Dell Monitor | |

| Model L Adjustable Mounting Kit |

Model M Adjustable Mounting Kit |

Model M Adjustable Mounting Kit |

5 MP Mono Color Camera |

|

| Telecentric Lens | ||||

| Model M Adjustable Mounting Kit | ||||

| Client Software | Smart Object Counting | Smart Offset Measurement | Smart Template Matching | Smart Advanced Defect Detection |

| Operating System | Linux | Linux | Linux | Linux |

| Working Temperature | 0 °C to 50 °C | 0 °C to 50 °C | 0 °C to 50 °C | 0 °C to 50 °C |

| Humidity | 20% to 80% RH, without condensation |

20% to 80% RH, without condensation |

20% to 80% RH, without condensation |

20% to 80% RH, without condensation |

| Dimension | 480 (L) * 360 (W) * 608(H) mm | 260 (L) * 200 (W) * 392(H) mm | 260 (L) * 200 (W) * 392(H) mm | 260 (L) * 200 (W) * 392(H) mm |

| Weight | 10kg | 8kg | 8kg | 8kg |

| Region of Interest | 250 (L) * 320 * (W) * 25 (H) mm | 80 (L) * 80 * (W) * 40 (H) mm | 80 (L) * 80 * (W) * 40 (H) mm | 80 (L) * 80 * (W) * 40 (H) mm |

| Operating Voltage | 5.1V DC | 5.1V DC | 5.1V DC | 240V AC |

| Operating Current | 3.0 A | 3.0 A | 3.0 A | 8.0 A |

| Sensor | 1.3 MP, 1/3" CCD, Area Scan Mono Camera |

1.3 MP, 1/3" CCD, Area Scan Mono Camera |

1.3 MP, 1/3" CCD, Area Scan Mono Camera |

5.0 MP 2/3" CMOS USB 3.0 Mono Camera |

| Pixel Size | 3.75 µm* 3.75 µm | 3.75 µm* 3.75 µm | 3.75 µm* 3.75 µm | 3.45 μm * 3.45 μm |

| Resolution | 1280 * 960 pixel | 1280 * 960 pixel | 1280 * 960 pixel | 2448 * 2048 pixel |

| Max. Frame Rate | 30 frame per second (fps) | 30 frame per second (fps) | 30 frame per second (fps) | 35 frame per second (fps) |

| Exposure Time | 10 μs to 1 s | 10 μs to 1 s | 10 μs to 1 s | 50 μs to 10 s |

Get Started

Get in touch with our sales team and request quote for the product & services you are looking for.

REQUEST QUOTE